DESCRIPTION OF THE PROJECT

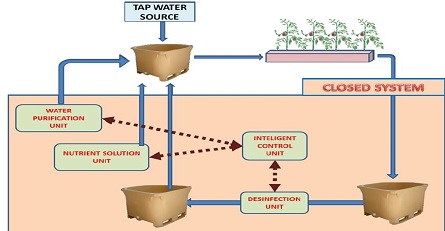

Open hydroponic systems are widely present in the European modern agriculture. However, in open hydroponic systems drainages are released into the environment. The drainages are composed by 31% of nitrates, and 48% of potassium applied as fertilizers, with the concomitant pollution and eutrophication of land and water. As an alternative to open hydroponic systems, a full re-circulation system , also known as closed system, have been developed in The Netherlands, but the percentage of producers that use it in their greenhouses in the rest of Europe is very low manily because these systems need to be specifically designed and adjusted to the specific conditions where production is taken place. For that reason the aim of the present project is to demonstrate the feasibility of using a full re-circulation systems for soilless culture in the Euro-Mediterranean region, where more than the 60% of Greenhouse production takes place.This aim will be achieved through a modular and scalable pilot system, easily adaptable to most of the agricultural scenarios in south Europe by just modifying the capacity of their components. The demonstration of a pilot system at a 1:10 scale becomes necessary for identifying potential problems, costs, energy consumption, optimization of key steps and software depuration. The system will be dimensioned as a function of the volume of drainages per day that needs to be recirculated.

The aim of the project will be achieved through the next specific objectives:

OBJECTIVES OF THE PROJECT

- To demonstrate through the design, construction and set up of a full re-circulation pilot system the technological possibility for Euro-Mediterranean regions of drainage reuse. The pilot system will be assayed in tomato plants, one of the most economically important and extended crop in south Europe. The pilot system proposed here will be able to collect the drainages coming from the normal irrigation of the tomato plantation, to disinfect them and to adjust the nutrient concentration, pH and electrical conductivity with the purpose of making drainages re-usable for a new irrigation cycle.

- To propose a legal and regulatory framework for drainage recirculation to Euro-Mediterranean regulatory bodies.

- To disseminate to all interested stakeholders, the benefits of full recirculation systems as an environmental friendly solution for drainage release of hydroponic greenhouses.

ACTIONS

A. Preparatory actions (if needed)

A1 Assessment of soilless cultures in European countries; crops, technologies and operating conditions

A2 Definition of nutrients solution for soilless horticulture production

B. Implementation actions (obligatory)

B1 Characterization of nutrient cycle for soilless tomato production

B2 Pilot plant design of the integrated system for water reuse and recycling

B3 Construction of the integrated system for water closed cycle

B4 Pilot plant set-up, and follow up

B5 Demonstration of water closed cycle in soilless tomato production

B6 Economic feasibility analysis

B7 Legal feasibility analysis

B8 Transferibility of LIFE DRAINUSE results

C. Monitoring of the impact of the project actions (obligatory)

C1 Efectiveness of LIFE DRAINUSE actions as compared to the initial situation

C2 Monitoring the socio-economic impact of the project on the local economy and population

D. Public awareness and dissemination of results (obligatory)

D1 Dissemination of the project results

D2 Elaboration of project website

D3 Elaboration of the Layman’s Report

D4 Elaboration and maintenance of Notice Boards

E. Project management and monitoring of the project progress (obligatory)

E1 Project management by CSIC

E2 Networking activities with other projects

E3 After LIFE Plan

E4 Compilation of information for indicator tables

EXPECTED RESULTS

Result 1. Water savings.

Result 2. Fertilizers saving

Result 3. Money saving.

Result 4. Environment enrichment and protection..

Result 5. Reactivation of the local economy.

700 m3 of water per ha per year reused

No reduction of production or quality respect to

Increase in water use efficiency of 20-50%)

35% of saving of nitrogen fertilizer used per ha.

20% of saving of phosphorus fertilizer used per ha.

17% of saving of potassium fertilizer used per ha.

No release of drainages, N, P or K to the environment